Discover Triton – your key to efficient water filtration!

Triton is not just a filter bottom system – it is an innovation that revolutionizes treatment in wastewater and water treatment plants. Designed to work with filter media such as sand or activated carbon, it is often used as final polishing to deliver the purest water.

With its stainless steel bottom filter system placed in the basin, Triton offers a unique advantage for customers: low pressure drop and efficient backwashing. This means you get high-quality filter media after each wash, resulting in longer operating periods and higher productivity.

Our 20 years of experience collaborating with Johnson Screens, our French supplier, has resulted in more than sixty installed drinking water and wastewater plants across Sweden and Norway. Whether it concerns building new plants or renovating existing ones, you can rely on us to deliver reliable and cost-effective solutions.

Choose Triton and experience the benefits of long operating periods, high productivity, and increased profitability for your plant!

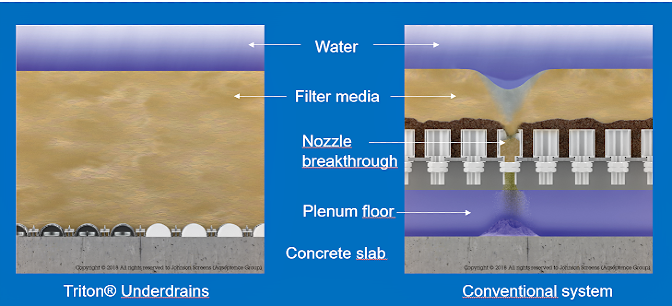

The Triton® system is designed to solve typical problems that arise in filtration plants and offers several advantages compared to conventional filter bottom systems. The Triton® drainage system utilizes Johnson’s world-renowned patented Vee Wire® slot technology. With its unique system, it can easily be adapted to almost any existing filter bottom, which shortens renovation time and reduces investment costs. The Triton® filter bottom system increases the active treatment area.

Advantages of a Triton® filter

- Simple filter design

- Material AISI 304L or 316L

- Increased filter area by 110–120%

- Vee-Wire® slots (patented) to fit different types of media and sizes

- Slot openings of 0.3 mm as standard

- No need for support gravel (filter media applied directly on Triton® filter cassettes)

- Ideal for renovation

- Reduced clogging problems

- Covers the entire filter area

- More efficient backwashing

- Backwashing with air/water or with water only (recommended backwash velocity in the filter is 40–60 m/h)

- Low initial pressure drop

- Several filter layers can be used without risk

- The system can utilize all known filter media on the market (Sand, Activated Carbon, Green Sand, Anthracite, Filtralite, etc.)

- Fewer backwash cycles, providing higher productivity (m³/m²)

- Energy savings thanks to more efficient washing

- Filter cassettes can be removed if necessary without intervention in the construction

Comparison with conventional filter bottoms

What are your requirements?

The Triton® filter bottom system is modular and scalable. It can be built on site or prefabricated. Old filter systems with conventional bottom nozzles can easily be replaced. Triton® does not require double filter bottoms. In addition, the active filtration area increases by 20 percent thanks to the U-shaped filter cassettes.

For more information or inquiries, please contact me