Unique advantages

Improved dewatering

When phosphate levels in digested sludge are high, for example in a Bio-P plant, the water-binding capacity of EPS (extracellular polymeric substances) and proteins increases. This makes the sludge more difficult to dewater. By precipitating the dissolved phosphates with the help of ELOVAC®-P, dewatering is therefore improved. Digested sludge from the wastewater treatment plant in Lingen, Germany, was examined before and after the use of ELOVAC®-P. Analyses showed that dewatering improved by more than 5 percentage points, which reduced disposal costs by about 20%.

Prevent struvite formation

Since vacuum degassing, in addition to methane, also drives carbon dioxide out of the sludge, the pH value increases slightly. This, together with the dosing of magnesium chloride, creates perfect conditions for controlled struvite precipitation in the ELOVAC®-P reactor. The microcrystals formed remain in the sludge and do not adhere to pipes, tanks, or dewatering equipment, i.e., problems with struvite precipitation downstream are significantly reduced.

Compact and easy-to-install system

With ELOVAC®-P, struvite precipitation occurs differently compared to conventional struvite recovery techniques: there is no growth of struvite crystals and the crystals are not separated. The technical solution therefore has unique advantages: the reactor tank can have a very small volume (about 50 times smaller than a standard solution) since the chemical reaction takes seconds rather than hours. With ELOVAC®-P, one also avoids having dewatering equipment affected by struvite crystals with abrasive properties.

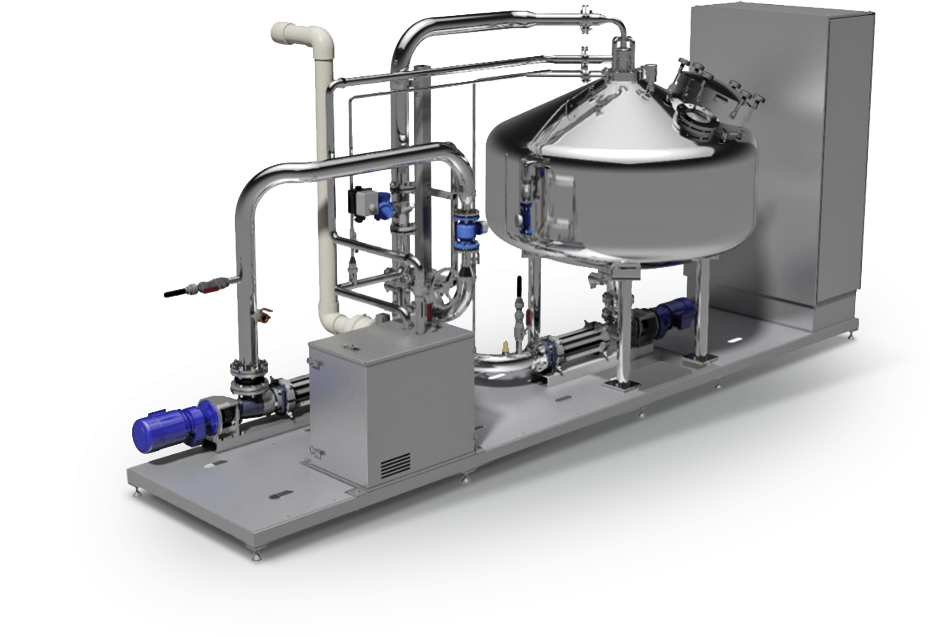

ELOVAC® is a modular system suitable for plants of all sizes. ELOVAC® is available in different versions with a digested sludge throughput between 10 m³/h and 50 m³/h. The system is delivered pre-assembled on skids, requiring minimal installation work on site. ELOVAC® can be installed inside a building or in a container.

Reduced climate footprint

After digestion, the sludge still contains methane in dissolved form and as microbubbles. This methane, which is harmful to the climate, is released into the atmosphere during storage and dewatering of the sludge. By capturing this methane and directing it to the gas system, ELOVAC® improves the climate footprint both by reducing emissions and by increasing gas production. ELOVAC® has a positive energy balance.

Improved sludge quality

Struvite is a long-acting fertilizer with high plant availability. With ELOVAC®-P, the fertilizer value of the sludge is improved since the small struvite crystals remain in the dewatered sludge.

ELOVAC® |

ELOVAC®-P |

|

|---|---|---|

| Vacuum degassing |

Vacuum degassing + phosphate precipitation | |

| Improved dewatering | ||

| Reduced polymer consumption | ||

| Compact system and easy installation | ||

| Prevents struvite formation | ||

| Reduced phosphate load | ||

| Generates biogas (positive energy system) | ||

| Improved sludge quality | ||

| Reduced greenhouse gas emissions |

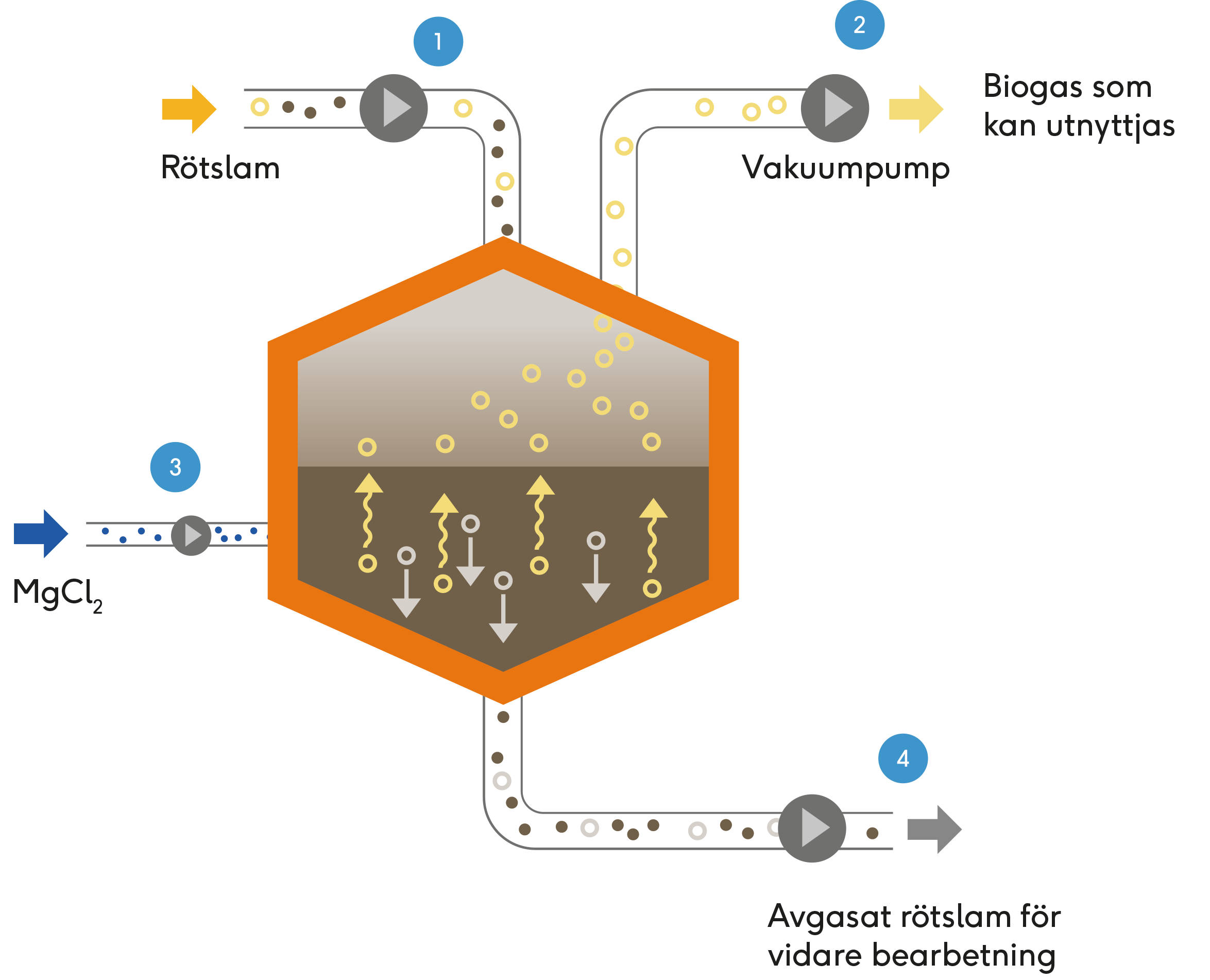

How it works

The sludge is continuously fed into the reactor tank for degassing.

A vacuum pump extracts methane and CO₂ from the digested sludge, which increases the pH value in the reactor tank. Thanks to the gas being vacuum extracted, the operation achieves a positive energy balance since biogas is captured while greenhouse gas emissions are reduced.

MgCl2 is added in the reactor tank. The higher pH value ensures that struvite formation is controlled and that no large crystals are formed. Processing time ~ 10 minutes.

The degassed sludge with the precipitated struvite is continuously discharged for dewatering.

Phosphate precipitation, compact, easy-to-install and pre-assembled.

ELOVAC® is scalable

| ELOVAC ® -model |

Dimensions |

Capacity sludge flow |

Plant size |

|---|---|---|---|

| 20 | 1,8 m x 5,5 m | 5 - 20 m3/h | < 400 000 |

| 30 | 2,5 m x 6,5 m | 10 - 30 m3/h | < 600 000 |

| 40 | 2,5 m x 7,3 m | 15 - 40 m3/h | < 750 000 |

After we introduced a vacuum degassing system with phosphate precipitation – ELOVAC® – we no longer have problems with struvite formation. With ELOVAC® we not only avoid operational disturbances, we also save on sludge disposal and polymers.

QUOTE FROM THE MANAGEMENT AT LINGEN WWTP (EMS)

Is ELOVAC® the right choice for your wastewater plant?

- Do you have high sludge disposal costs?

- Do you have problems with struvite formation?

- Do you have Bio-P?

- Do you aim to reduce the carbon footprint of your operations?

- Is the fertilizer value of the sludge important to you?